Get SMS verification code

2022-06-02

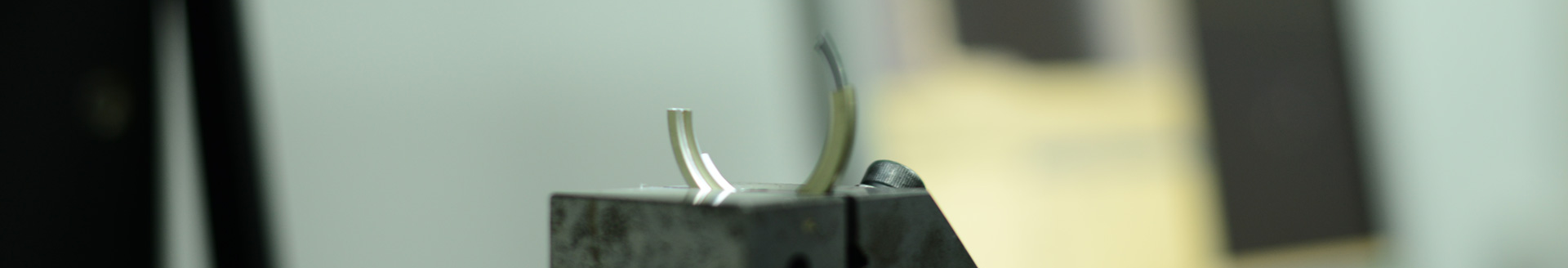

Spherical plain bearingis a spherical sliding bearing, its sliding contact surface is an inner spherical surface and an outer spherical surface, the movement can be rotated at any angle swing, it uses surface phosphating, blowing mouth, inlay pad, spraying, and other special technology processing methods to make. The spherical plain bearinghas a large load capacity, impact resistance, corrosion resistance, wear resistance, self-aligning, good lubrication, and other characteristics.

The structure of spherical plain bearings is simpler than rolling bearings, which mainly consists of an inner ring with an outer spherical surface and an outer ring with an inner spherical surface. Spherical plain bearings are generally used for low-speed oscillating motion (i.e. angular motion), due to the sliding surface for the spherical shape, also in a certain angle range for tilting motion (i.e. spherical motion), in the support shaft and shaft shell-hole is not the same as the larger, but still can work properly.

The spherical plain bearingcan bear a large load. According to its different types and structure, it can bear radial load, axial load, or radial, axial at the same time as the combined load. As the outer spherical surface of the inner ring is inlaid with composite material, so the bearing can produce self-lubrication in the work. Generally used for low-speed swing movement, and low-speed rotation, but also in a certain angle range for tilting movement, when the support shaft and shaft shell-hole is not the center degree is large, but still can work normally. Self-lubricating spherical plain bearings are used in water conservancy, professional machinery, and other industries.

Spherical plain bearingis mainly composed of an outer ring and an inner ring. The inner spherical surface of the outer ring and the outer spherical surface of the inner ring form a rolling friction pair.

Because the structure form and working mechanism of spherical plain bearings are completely different from rolling bearings, so spherical plain bearings have their own technical characteristics and maintenance requirements.

The loading and unloading of spherical bearings should follow the following principles, namely, the force exerted by assembly and disassembly cannot be transmitted directly through the spherical sliding surface. In addition, auxiliary loading and unloading tools should be used, such as sleeves, dismantlers, etc., the external loading and unloading force applied directly and uniformly on the matched ring, or heating and other auxiliary methods for loading and unloading without load.

When assembling the spherical plain bearingseries, it is necessary to pay special attention to the location of the outer ring split surface. In order to avoid the direct action of the load on the split surface, the split surface should be maintained at right angles to the direction of compliance.

When the applied load and the speed generated by the oscillating motion are very small, oil-fed spherical bearings can be operated without lubrication. Nevertheless, it is necessary to replenish grease regularly in general. In the initial installation and operation, it is recommended that the lubrication interval should be moderately shortened.

Oil-free spherical plain bearings can be used without lubrication. However, if lithium soap-based grease is added prior to operation, the service life of the spherical plain bearing can be extended even further. If the space around the bearing is filled with grease, the spherical bearing will be more effective in protecting against dust and foreign objects.

We are a spherical plain bearing supplier. If you are interested in our products, please contact us now!

Copyright:Dalian Ounuo Bearing Co., Ltd

Sitemap

zhangxiao01@hotmail.com

+19093438885